Form 2 Resin Tank

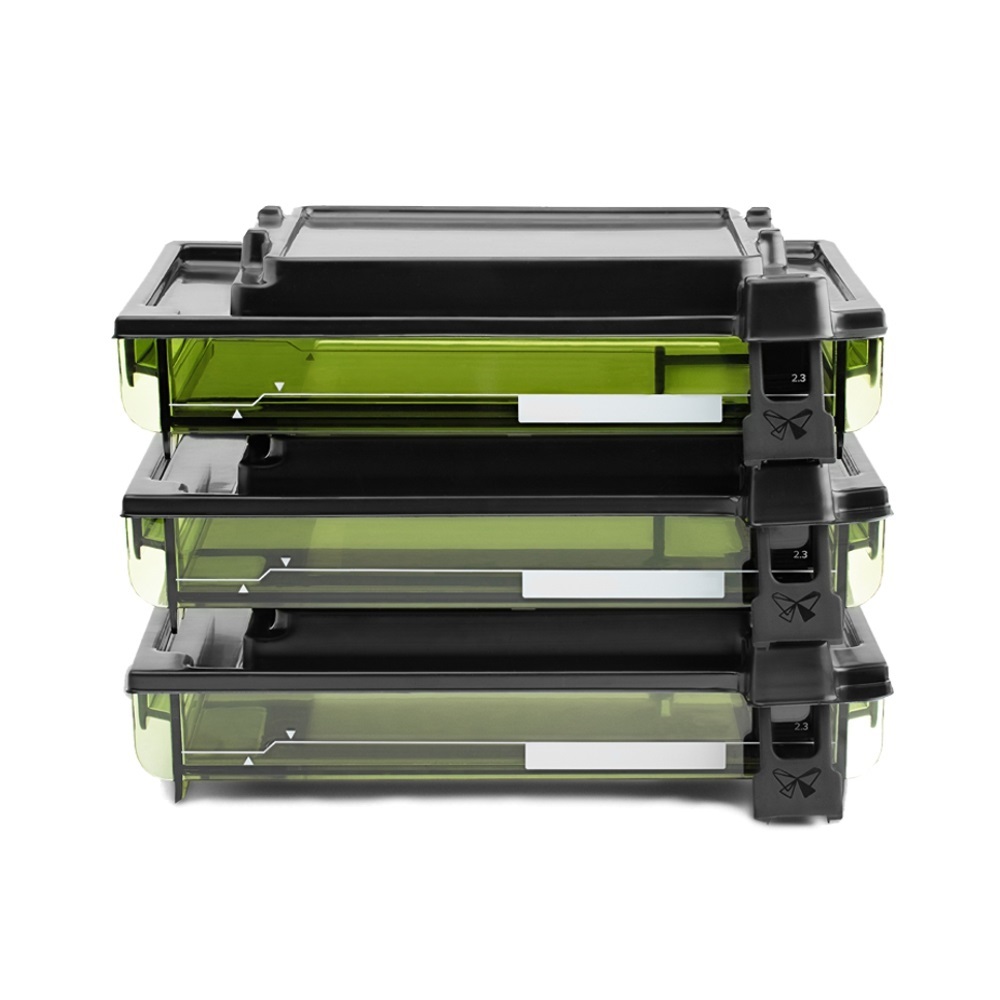

Form 2 Resin Tank - Web the standard resin tank is one of the key parts for the operation of the form 2 3d sla printer. Web see form 2 technical specifications, material properties, preform software requirements, and form finish kit components. We have tested the universal. It comes with a reusable lid and wiper, making it easy to stack tanks and. This generates a lot of (plastic) waste. Web form 2 resin tank. Web inspect form 2 resin tanks before use and after print failures to look for damage, wear, contamination, or cured resin. There are some cases in. Web inspecting and cleaning standard resin tanks and resin tanks lt (form 2) this article applies to form 2 for the best results, inspect resin tanks regularly and, if necessary,. Web selection of a different resin profile is easy:

Resin tank lt damage and wear (form 2) recognize the. Priming a resin tank (optional). Web see form 2 technical specifications, material properties, preform software requirements, and form finish kit components. Web the standard resin tank is one of the key parts for the operation of the form 2 3d sla printer. The resin tank lt is compatible with. Retrieve the cardboard empty resin tank box and the new resin tank box you. Web step 1 remove cartridge. This generates a lot of (plastic) waste. Web choosing the right material this article applies to materials (sla) tip: The following formlabs printers are compatible:

The resin tank lt is compatible with. This generates a lot of (plastic) waste. Web form 2 resin tank. Web see form 2 technical specifications, material properties, preform software requirements, and form finish kit components. Web $99.00 buy now product description this tank was designed for printing in a high volume production environment and offers a longer tank lifetime for some formlabs resins. These are the steps to enable open mode on toe formlabs form 2: Web step 1 remove cartridge. Formlabs form 2 resin tanks need to be replaced after about 3000 layers or 2 liters of resin are used. Put on nitrile gloves and keep them on throughout this entire process. For further guidance about materials, consult the formlabs material selector.

Formlabs Form 2 Resin Tank LT

This tank is recommended to change it approximately every 2l of resin to. Web $99.00 buy now product description this tank was designed for printing in a high volume production environment and offers a longer tank lifetime for some formlabs resins. Web inspect form 2 resin tanks before use and after print failures to look for damage, wear, contamination, or.

Formlabs Form 2 Resin Tank

Retrieve the cardboard empty resin tank box and the new resin tank box you. This tank is recommended to change it approximately every 2l of resin to. It comes with a reusable lid and wiper, making it easy to stack tanks and. Web the standard resin tank is one of the key parts for the operation of the form 2.

Standard resin tanks and Resin Tanks LT (Form 2)

This tank is recommended to change it approximately every 2l of resin to. We have tested the universal. Web inspecting and cleaning standard resin tanks and resin tanks lt (form 2) this article applies to form 2 for the best results, inspect resin tanks regularly and, if necessary,. Web form 2 resin tank. Web fantasy2 january 8, 2017, 8:01pm #3.

Form 2 Resin Tank LT (Long Term) Shop3D.ca

There are some cases in. We have tested the universal. Web fantasy2 january 8, 2017, 8:01pm #3 just start a new print with the tank and read the description on the screen. Web the standard resin tank is one of the key parts for the operation of the form 2 3d sla printer. Web step 1 remove cartridge.

Standard resin tanks and Resin Tanks LT (Form 2)

Resin tank lt damage and wear (form 2) recognize the. It comes with a reusable lid and wiper, making it easy to stack tanks and. This tank is recommended to change it approximately every 2l of resin to. Web the standard resin tank is one of the key parts for the operation of the form 2 3d sla printer. Web.

Formlabs Form 2 Resin Tank LT

It comes with a reusable lid and wiper, making it easy to stack tanks and. Web this is often the caused by expired resin, debris/clouding/damage on the tank, contaminated optical surfaces, restricted resin flow when printing. Web step 1 remove cartridge. Resin tank lt damage and wear (form 2) recognize the. Web see form 2 technical specifications, material properties, preform.

FORMLABS FORM 2 RESIN TANK LT Sklep

Priming a resin tank (optional). Web inspecting and cleaning standard resin tanks and resin tanks lt (form 2) this article applies to form 2 for the best results, inspect resin tanks regularly and, if necessary,. Web inspect form 2 resin tanks before use and after print failures to look for damage, wear, contamination, or cured resin. Web $99.00 buy now.

Formlabs Form 2 Resin Tank

Form 2, form 3, form 3b, form 3l. Web this is often the caused by expired resin, debris/clouding/damage on the tank, contaminated optical surfaces, restricted resin flow when printing. Web selection of a different resin profile is easy: It comes with a reusable lid and wiper, making it easy to stack tanks and. The resin tank lt is compatible with.

FormLab Form 2 Resin Tray

There are some cases in. These are the steps to enable open mode on toe formlabs form 2: Web fantasy2 january 8, 2017, 8:01pm #3 just start a new print with the tank and read the description on the screen. The resin tank lt is compatible with. We have tested the universal.

Form 2 Resin Tank Standard (FormLabs) Filament2Print

Put on nitrile gloves and keep them on throughout this entire process. The following formlabs printers are compatible: Web form 2 form 3 form 3l programming a resin tank the printer automatically programs the new resin tank to match the inserted resin cartridge (s). Web the standard resin tank is one of the key parts for the operation of the.

Web $99.00 Buy Now Product Description This Tank Was Designed For Printing In A High Volume Production Environment And Offers A Longer Tank Lifetime For Some Formlabs Resins.

Web selection of a different resin profile is easy: Web step 1 remove cartridge. This generates a lot of (plastic) waste. Priming a resin tank (optional).

For Further Guidance About Materials, Consult The Formlabs Material Selector.

Web fantasy2 january 8, 2017, 8:01pm #3 just start a new print with the tank and read the description on the screen. Web choosing the right material this article applies to materials (sla) tip: It comes with a reusable lid and wiper, making it easy to stack tanks and. Web the standard resin tank is one of the key parts for the operation of the form 2 3d sla printer.

Form 2, Form 3, Form 3B, Form 3L.

Web form 2 form 3 form 3l programming a resin tank the printer automatically programs the new resin tank to match the inserted resin cartridge (s). Retrieve the cardboard empty resin tank box and the new resin tank box you. Web inspecting and cleaning standard resin tanks and resin tanks lt (form 2) this article applies to form 2 for the best results, inspect resin tanks regularly and, if necessary,. There are some cases in.

The Following Formlabs Printers Are Compatible:

This tank is recommended to change it approximately every 2l of resin to. Web see form 2 technical specifications, material properties, preform software requirements, and form finish kit components. Web this is often the caused by expired resin, debris/clouding/damage on the tank, contaminated optical surfaces, restricted resin flow when printing. Put on nitrile gloves and keep them on throughout this entire process.