Form 3 Resin

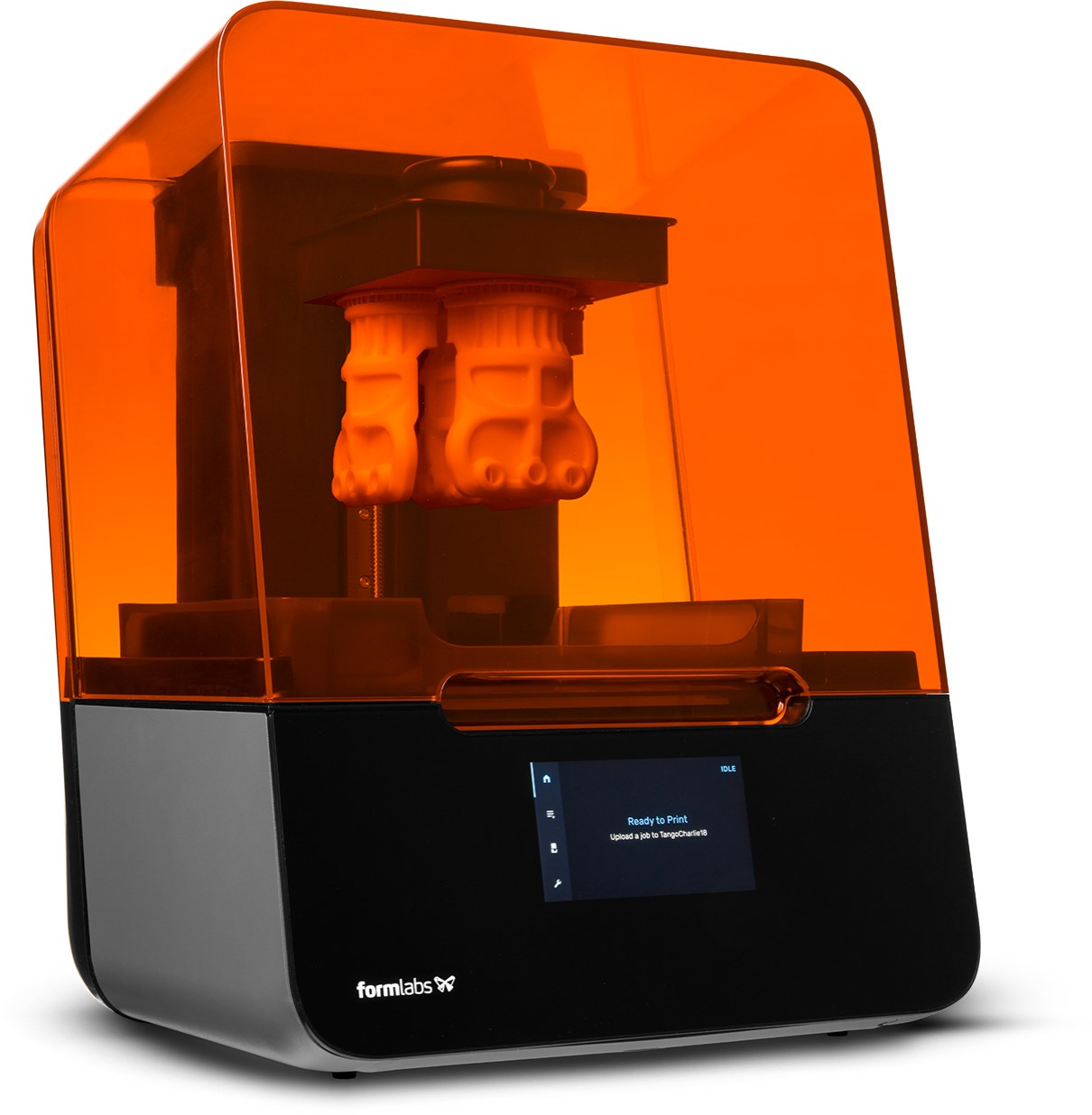

Form 3 Resin - Web the form 3/form 3b resin tank is the primary container for holding resin after it is dispensed from the cartridge. Web architectural resin and glass | acoustics | partitions | 3form ivory flora a new approach and perspective on biophilic design redefining what organics can look like in a space. Web medical resins 3d printing materials for healthcare. Web the form 3l offers automatic resin dispensing, simple print preparation software, and a thoughtfully designed interface. Web formlabs develops the form 3+ and form 3l low force stereolithography (lfs) and fuse 1+ selective laser sintering (sls) 3d printers for professionals. This advanced print process offers incredible print quality, surface detail, and a platform for more advanced materials and applications. There are cheaper options such. I have printed a few test prints with the dental sg. We develop unique print settings for each resin and validate each individual layer thickness to ensure reliability and accuracy. The bottom of the form 3 resin tank is made of two layers of flexible film separated by an air gap.

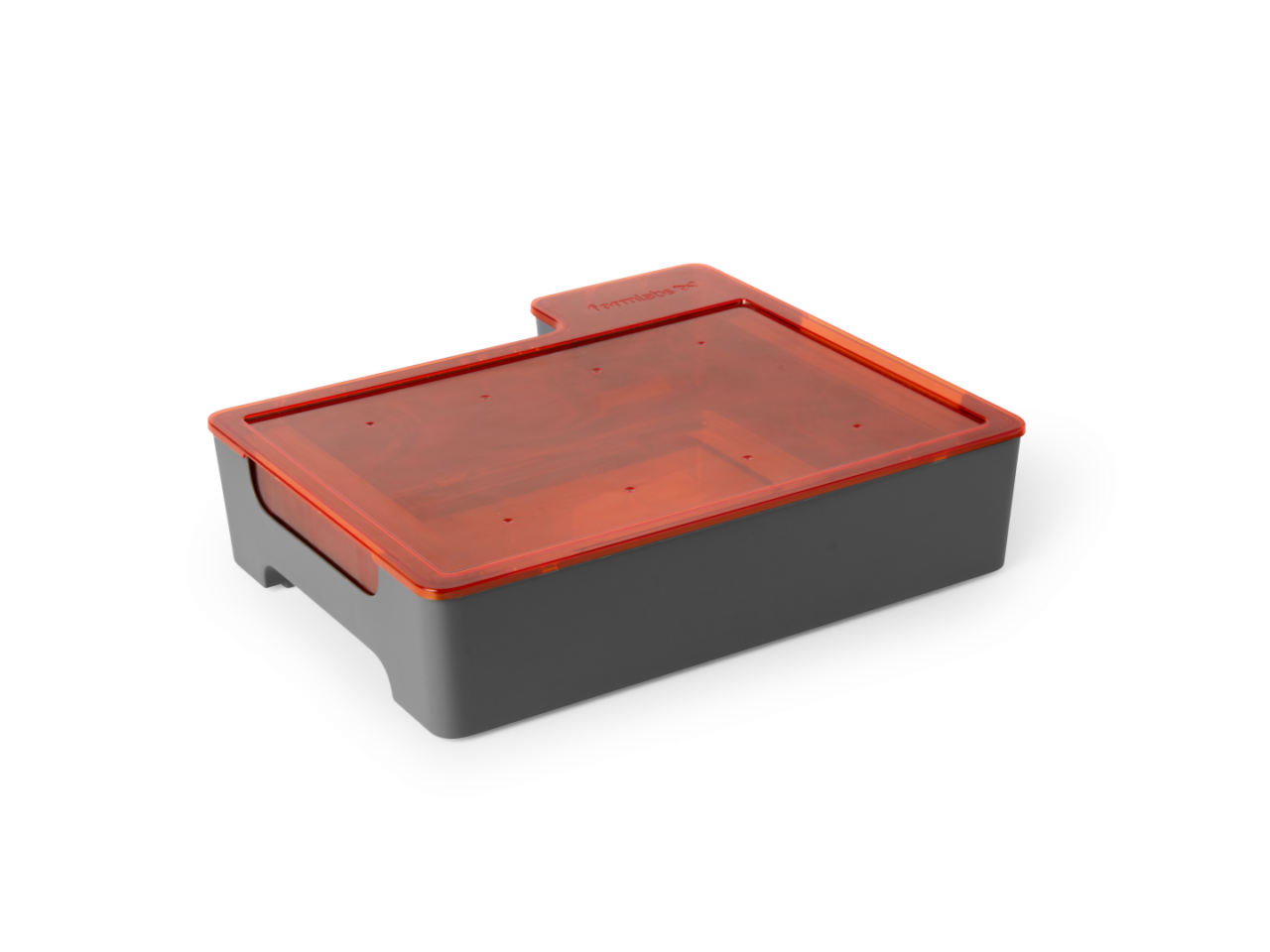

The bottom of the form 3 resin tank is made of two layers of flexible film separated by an air gap. Be sure to handle and maintain the tank properly between each print. Web i am new to 3d printing here. Web medical resins 3d printing materials for healthcare. Resin is cured onto the build platform when the laser passes through the tank's bottom film. No i want to print a dental model with the model resin. For further guidance about materials, consult the formlabs material selector. Lfs resin tank damage and wear the bottom of the form 3 resin tank is made of two layers of flexible film separated by an air gap. Access a library of over 20 materials available on one powerful desktop 3d printer, the form 3b+. Web begin the process of reprogramming a resin tank on a form 3l/form 3bl using the printer’s touchscreen.

For further guidance about materials, consult the formlabs material selector. This advanced print process offers incredible print quality, surface detail, and a platform for more advanced materials and applications. But you would need a universal cartridge by protoart to be able to use these resins in the printer. Web the form 3+ turns liquid resin into flawless parts with low force stereolithography (lfs)™ which consistently delivers presentation ready parts with unbelievable surface finish. Be sure to handle and maintain the tank properly between each print. Lfs resin tank damage and wear the bottom of the form 3 resin tank is made of two layers of flexible film separated by an air gap. I have all this resin sitting on the bottom of the form 2 resin tank. The bottom of the form 3 resin tank is made of two layers of flexible film separated by an air gap. For use with form 3 and form 3b. Web formlabs develops the form 3+ and form 3l low force stereolithography (lfs) and fuse 1+ selective laser sintering (sls) 3d printers for professionals.

Formlabs Form 3+ Extended Complete Package Shop3D.ca

We develop unique print settings for each resin and validate each individual layer thickness to ensure reliability and accuracy. There are cheaper options such. But you would need a universal cartridge by protoart to be able to use these resins in the printer. This advanced print process offers incredible print quality, surface detail, and a platform for more advanced materials.

Form 3 Resin Tank v2.1 DDD Printers

Web medical resins 3d printing materials for healthcare. High resolution sla and sls 3d printers for professionals | formlabs Artists, designers and professionals who rely on 3d printing will find this cost acceptable. Biomed amber resin biomed black resin biomed clear resin biomed durable resin biomed white resin black resin castable resin castable wax resin castable wax 40 resin ceramic.

Formlabs Form 3+ Extended Complete Package Shop3D.ca

I have dental sg resin and the dental model 1l. There are cheaper options such. Web formlabs develops the form 3+ and form 3l low force stereolithography (lfs) and fuse 1+ selective laser sintering (sls) 3d printers for professionals. Web this article applies to materials (sla) tip: Web medical resins 3d printing materials for healthcare.

Form 3 Resin Printer MACCLab

But you would need a universal cartridge by protoart to be able to use these resins in the printer. Formable resin panels that let you play with endless combinations of color, texture, and light. Web access a library of over 20 materials available on one powerful desktop 3d printer, the form 3b+. During printing, the printer pulls on the film.

Form 3 Resin Tank

High resolution sla and sls 3d printers for professionals | formlabs I have all this resin sitting on the bottom of the form 2 resin tank. Web i am new to 3d printing here. Web this article applies to materials (sla) tip: The company’s latest drop includes both the form 3+ and the form.

FormLab Form 3 Resin Tank

Web access a library of over 20 materials available on one powerful desktop 3d printer, the form 3b+. I don’t want to waste it. The bottom of the form 3 resin tank is made of two layers of flexible film separated by an air gap. Web formlabs sla printers feature a resin handling system that automates resin dispensing during a.

Form 3 Resin Tank

During printing, the printer pulls on the film layers to. Web the form 3+ turns liquid resin into flawless parts with low force stereolithography (lfs)™ which consistently delivers presentation ready parts with unbelievable surface finish. Biomed amber resin biomed black resin biomed clear resin biomed durable resin biomed white resin black resin castable resin castable wax resin castable wax 40.

Form 3 Resin Tank 3DHUB.gr Το πρώτο 3D printing HUB στην Ελλάδα!

Web access a library of over 20 materials available on one powerful desktop 3d printer, the form 3b+. This advanced print process offers incredible print quality, surface detail, and a platform for more advanced materials and applications. Web formlabs develops the form 3+ and form 3l low force stereolithography (lfs) and fuse 1+ selective laser sintering (sls) 3d printers for.

3D принтер FormLabs Form 3 + (Form3 plus) Интернетмагазин «3DTool»

I have all this resin sitting on the bottom of the form 2 resin tank. But you would need a universal cartridge by protoart to be able to use these resins in the printer. The resin handling system includes the resin cartridge, resin tanks, the cartridge floor assembly,. Lfs resin tank damage and wear the bottom of the form 3.

Form 3 Resin Tank V2 .Z Universo 3D

Compare mechanical properties to find the resins that best match your product requirements. One of the most used is applylabwork resins. Web overview preparing the printer inspecting and cleaning external surfaces inspecting and cleaning components under the cover inspecting the z axis inspecting the resin tank inspecting the rollers and lpu cleanup contacting formlabs support preventing resin spills view all.

Artists, Designers And Professionals Who Rely On 3D Printing Will Find This Cost Acceptable.

Web there are several 3rd party resins compatible with the form 3 serie printers. Web the form 3/form 3b resin tank is the primary container for holding resin after it is dispensed from the cartridge. Web architectural resin and glass | acoustics | partitions | 3form ivory flora a new approach and perspective on biophilic design redefining what organics can look like in a space. Web formlabs develops the form 3+ and form 3l low force stereolithography (lfs) and fuse 1+ selective laser sintering (sls) 3d printers for professionals.

We Develop Unique Print Settings For Each Resin And Validate Each Individual Layer Thickness To Ensure Reliability And Accuracy.

Web the form 3 uses the same resin cartridges as the form 2, and we are working to make the full material library available for use on the form 3 over time. Download the full data sheet Web product description low force stereolithography (lfs)™ 3d printing uses linear illumination and a flexible film tank to turn liquid resin into flawless parts. One of the most used is applylabwork resins.

High Resolution Sla And Sls 3D Printers For Professionals | Formlabs

Web formlabs sla printers feature a resin handling system that automates resin dispensing during a print and tracks resin consumption. The company’s latest drop includes both the form 3+ and the form. How do i efficiently switch between resins? But you would need a universal cartridge by protoart to be able to use these resins in the printer.

Web Form 3/Form 3B Resin Tanks Can Be Reprogrammed And Used With A Different Resin Type.

Web the formlabs form 3 is the successor to the famed form 2. The bottom of the form 3 resin tank is made of two layers of flexible film separated by an air gap. This advanced print process offers incredible print quality, surface detail, and a platform for more advanced materials and applications. For use with form 3 and form 3b.