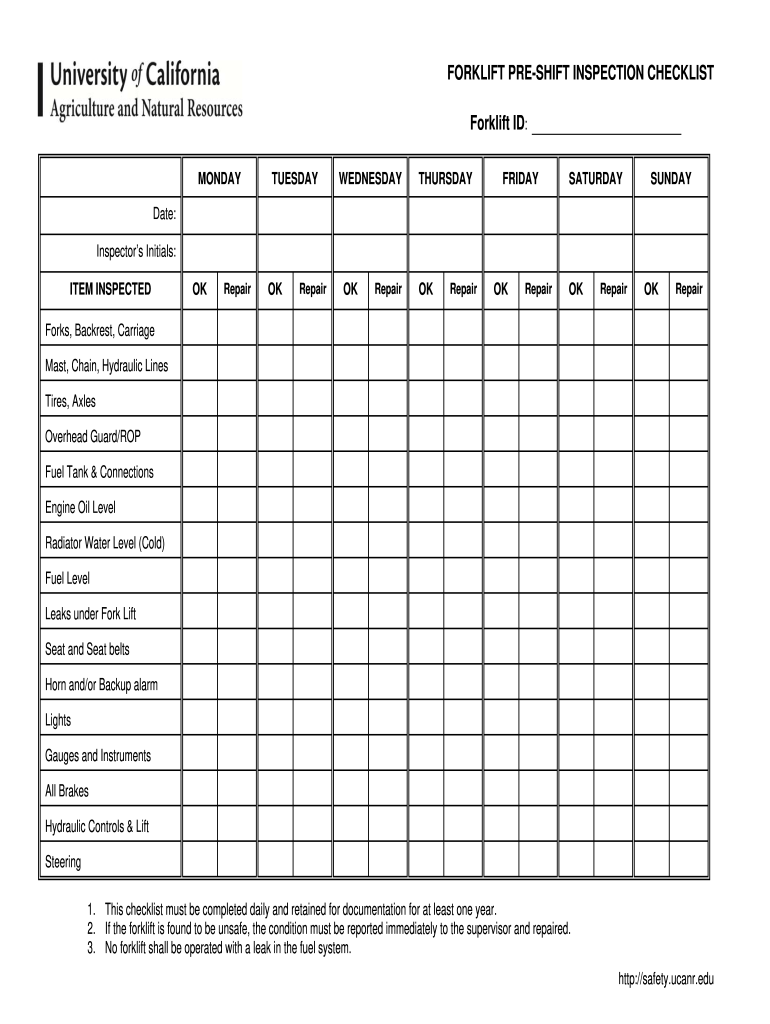

Printable Forklift Inspection Checklist

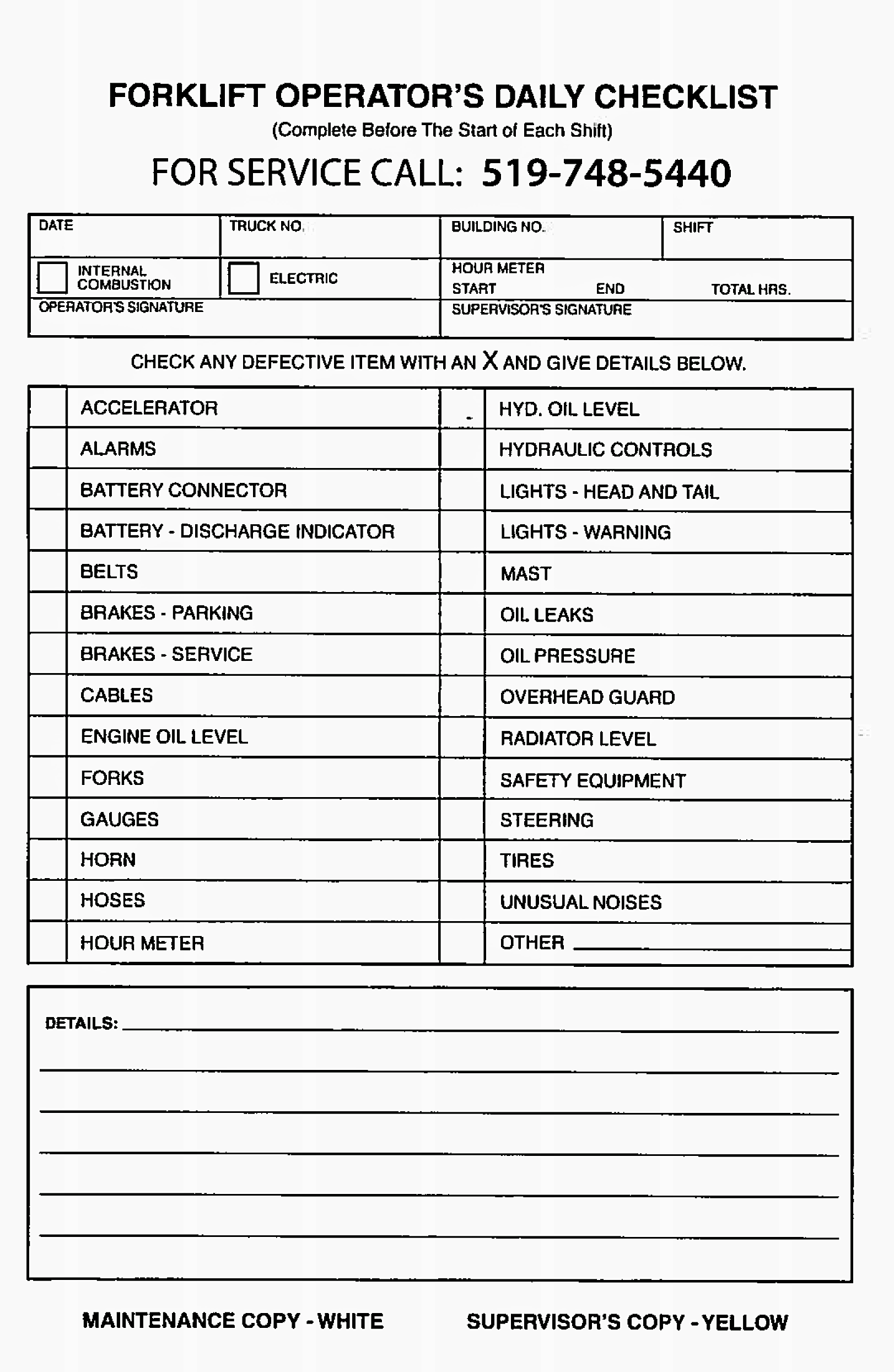

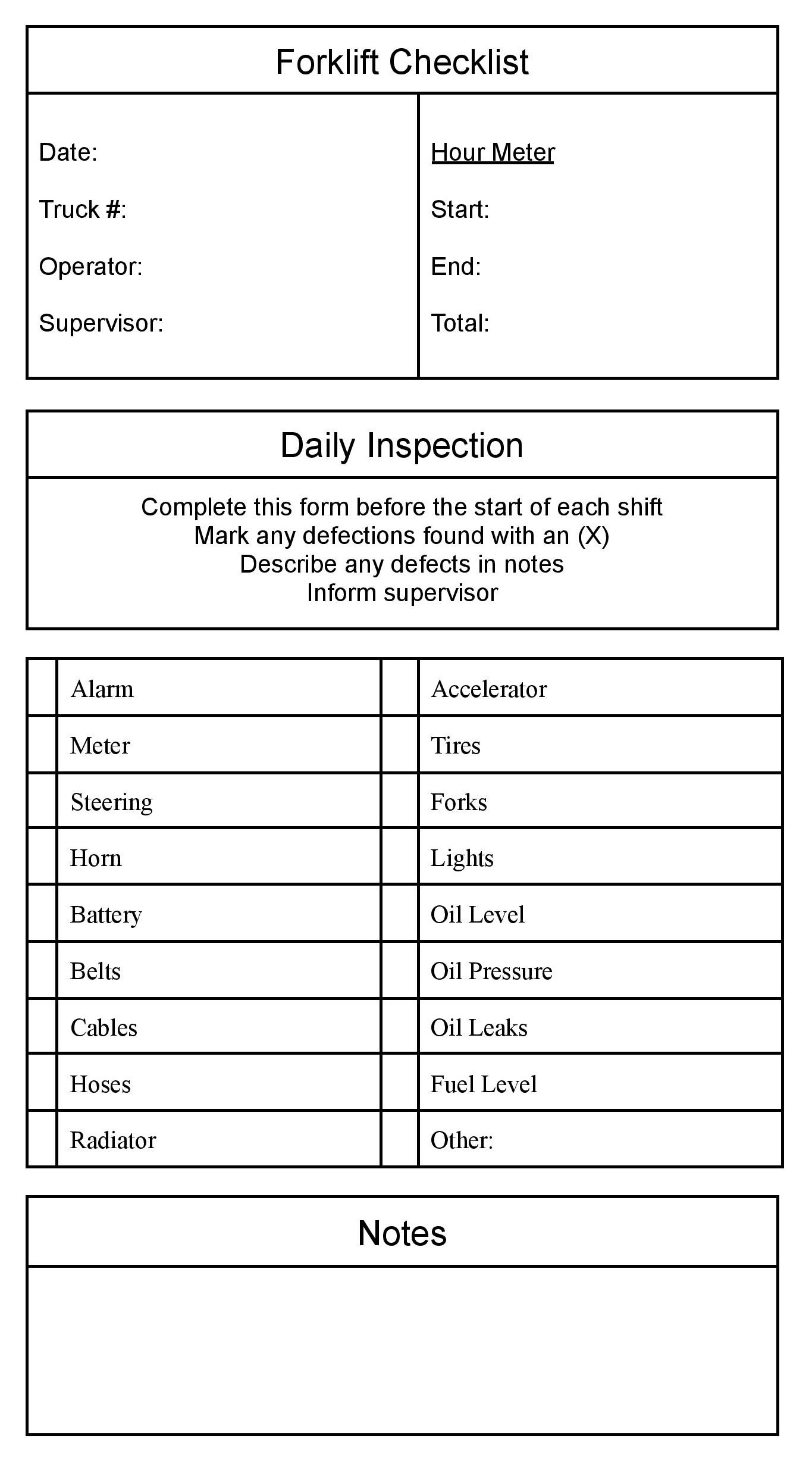

Printable Forklift Inspection Checklist - Testing your forklifts prior to every use reduces the risk of equipment being operated in a hazardous condition. The following checklists are provided for general use only and should be supplemented with good judgment and the recommendations of the manufacturer. Check for general damage and leaks. Web inspect the forklift before use. Here are 8+ forklift checklists to simplify the process and improve safety. Forklift operators can conduct pre operational checks using forklift checklist templates in the safetyculture forklift inspection app. Web this forklift inspection checklist contains over 30 inspection points to evaluate the condition and functioning of major components. Increase the longevity of your electric forklift and prevent injuries with this checklist. Web this checklist is designed to conduct a comprehensive safety inspection of the forklift to ensure compliance with osha regulations and identify potential safety hazards. Operators should complete the inspection process each day or shift, regardless of whom had previously operated the equipment.

For recordkeeping purposes, maintain this form on file when inspection has been completed. We’ve covered all major forklift inspection areas. Test mast chain tension by lifting the load backrest to eye level—the mast chains should be level and any tilting may signify stretching or broken rollers. General condition of the forklift. Here are 8+ forklift checklists to simplify the process and improve safety. Web this free pdf template covers all essential aspects of forklift safety, empowering you to identify potential hazards, perform regular inspections, and foster a secure work environment. Customize, print, share & use this list at: Add any pertinent comments in the space provided for each item checked “unsatisfactory.” include additional pages of explanation as necessary. Inspection must be done before each shift or before equipment is used for that day. Inspect the load before attempting to move it.

Operators should complete the inspection process each day or shift, regardless of whom had previously operated the equipment. The visual check involves the visual inspection of forklift components. Forklift operators can conduct pre operational checks using forklift checklist templates in the safetyculture forklift inspection app. Web this checklist is designed to conduct a comprehensive safety inspection of the forklift to ensure compliance with osha regulations and identify potential safety hazards. Check (.) each item below as “satisfactory” or “unsatisfactory” or “not applicable”. Inspection must be done before each shift or before equipment is used for that day. Testing your forklifts prior to every use reduces the risk of equipment being operated in a hazardous condition. Web our printable forklift checklist is perfect for every operation. The following checklists are provided for general use only and should be supplemented with good judgment and the recommendations of the manufacturer. Web check for leaks, cracks and visible defects everywhere on the forklift.

Printable Free Weekly Forklift Inspection Checklist Template

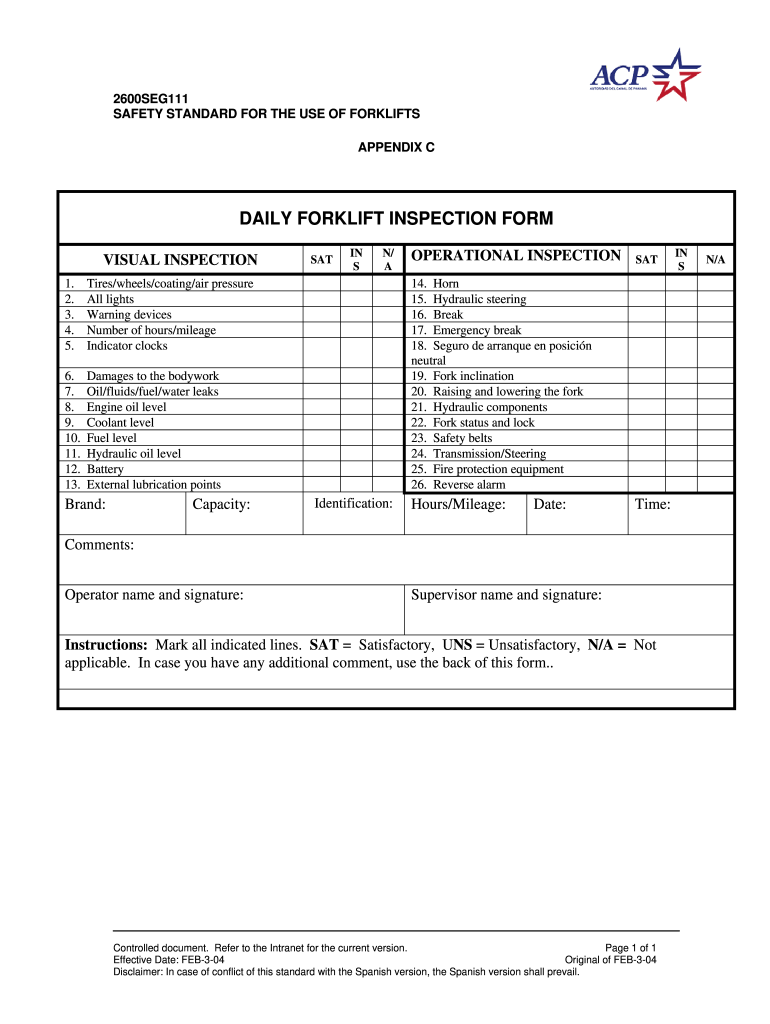

General condition of the forklift. Forklift operators can conduct pre operational checks using forklift checklist templates in the safetyculture forklift inspection app. Here are 8+ forklift checklists to simplify the process and improve safety. Web use this monthly forklift inspection template and other safety checklists to monitor improvements across your organization. Web daily forklift inspection checklist.

Printable Free Weekly Forklift Inspection Checklist Template

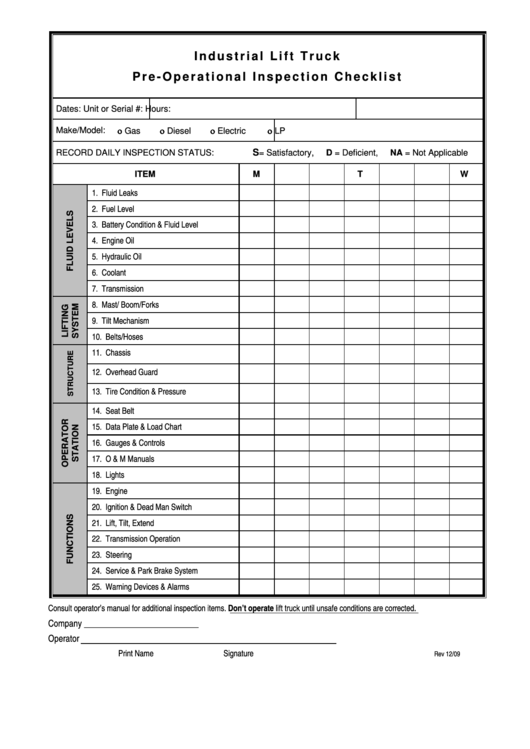

Any forklift operator should use a checklist for forklift inspection before operating the vehicle. Web the solution is a streamlined, templated checklist for forklift inspection. Increase the longevity of your electric forklift and prevent injuries with this checklist. Forklift operators can conduct pre operational checks using forklift checklist templates in the safetyculture forklift inspection app. For recordkeeping purposes, maintain this.

24+ Free Printable Forklift Inspection Checklist Templates Sample PDF

Ensure safety, save costs, improve productivity. Test mast chain tension by lifting the load backrest to eye level—the mast chains should be level and any tilting may signify stretching or broken rollers. Web run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. Inspection must be done before each.

Printable Free Weekly Forklift Inspection Checklist Template

Web download our forklift inspection checklist down below to ensure your trucks run to their maximum. Some areas which require checks are: Web inspect the forklift before use. For recordkeeping purposes, maintain this form on file when inspection has been completed. Check for mechanical damage and loose or leaking components.

Printable Forklift Inspection Checklist

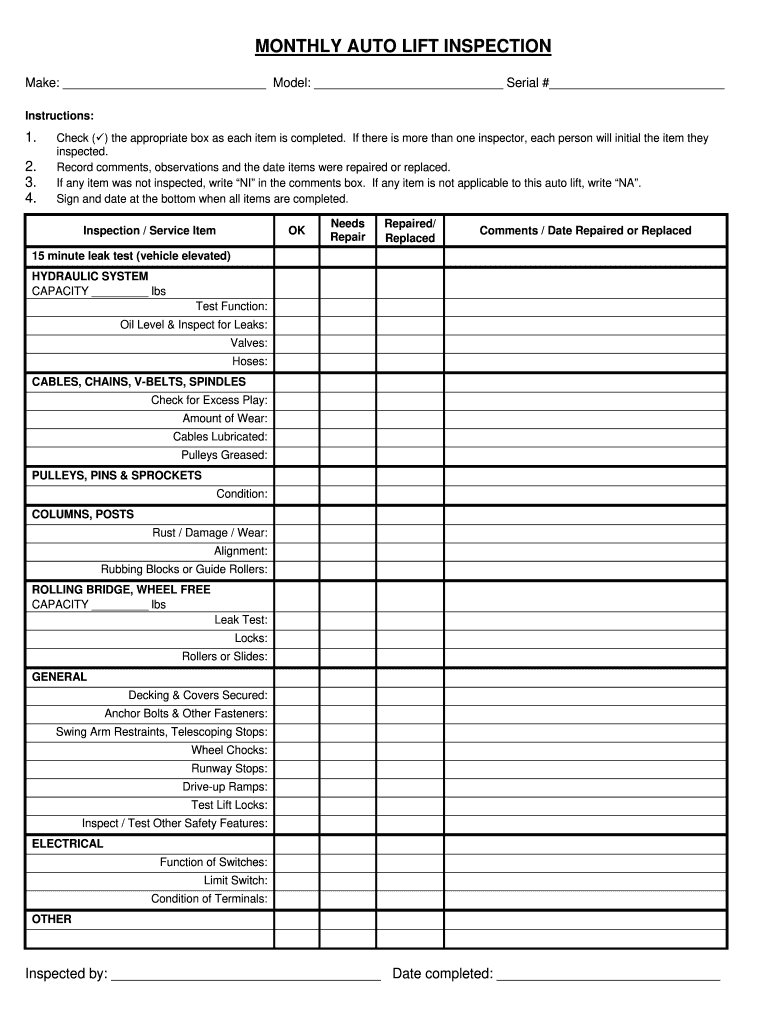

Web use this monthly forklift inspection template and other safety checklists to monitor improvements across your organization. Test mast chain tension by lifting the load backrest to eye level—the mast chains should be level and any tilting may signify stretching or broken rollers. We’ve covered all major forklift inspection areas. Inspection must be done before each shift or before equipment.

Printable Free Weekly Forklift Inspection Checklist Template

Check (.) each item below as “satisfactory” or “unsatisfactory” or “not applicable”. Web daily class i forklift inspection checklist. General condition of the forklift. Perform thorough visual checks on vehicle parts and systems. Web download free forklift checklists including forklift inspection checklist, forklift safety checklist, forklift daily checklist, and forklift pre start checklist.

24+ Free Printable Forklift Inspection Checklist Templates Sample PDF

Web check for leaks, cracks and visible defects everywhere on the forklift. Testing your forklifts prior to every use reduces the risk of equipment being operated in a hazardous condition. Web this checklist is designed to conduct a comprehensive safety inspection of the forklift to ensure compliance with osha regulations and identify potential safety hazards. Any forklift operator should use.

Printable Free Weekly Forklift Inspection Checklist Template

For recordkeeping purposes, maintain this form on file when inspection has been completed. Web this forklift inspection checklist contains over 30 inspection points to evaluate the condition and functioning of major components. Web this free pdf template covers all essential aspects of forklift safety, empowering you to identify potential hazards, perform regular inspections, and foster a secure work environment. Web.

Forklift Pre Shift Inspection Operator Checklist — WAYCO Best

Web our printable forklift checklist is perfect for every operation. Perform thorough visual checks on vehicle parts and systems. Web run this forklift inspection checklist before each shift to make sure that your machines are up to safety and operational standards. Operators should complete the inspection process each day or shift, regardless of whom had previously operated the equipment. Ensure.

Printable Free Weekly Forklift Inspection Checklist Template

Web daily forklift inspection checklist template: Any forklift operator should use a checklist for forklift inspection before operating the vehicle. General condition of the forklift. Web daily forklift inspection checklist. Web daily class i forklift inspection checklist.

Carefully Review Each Item And Mark The Corresponding Checkbox To Indicate Compliance Or Note Any Observations And Areas For Improvement.

Generally, you are checking to make sure that all required components are present and in good condition. Increase the longevity of your electric forklift and prevent injuries with this checklist. Test mast chain tension by lifting the load backrest to eye level—the mast chains should be level and any tilting may signify stretching or broken rollers. Operators should complete the inspection process each day or shift, regardless of whom had previously operated the equipment.

Web This Forklift Inspection Checklist Contains Over 30 Inspection Points To Evaluate The Condition And Functioning Of Major Components.

Some areas which require checks are: We’ve covered all major forklift inspection areas. Avoid the use of hands. Forklift operators can conduct pre operational checks using forklift checklist templates in the safetyculture forklift inspection app.

Web Use This Forklift Truck Pre Inspection Checklist To Assess Forklift Drivers’ Competency On Forklift Operations And Protocols.

Web this daily forklift inspection checklist empowers you to take control, safeguarding your team, your project, and the integrity of your equipment. Check for general damage and leaks. Web this checklist is designed to conduct a comprehensive safety inspection of the forklift to ensure compliance with osha regulations and identify potential safety hazards. Customize, print, share & use this list at:

Check (.) Each Item Below As “Satisfactory” Or “Unsatisfactory” Or “Not Applicable”.

General condition of the forklift. Web download free forklift checklists including forklift inspection checklist, forklift safety checklist, forklift daily checklist, and forklift pre start checklist. Any forklift operator should use a checklist for forklift inspection before operating the vehicle. Inspection must be done before each shift or before equipment is used for that day.